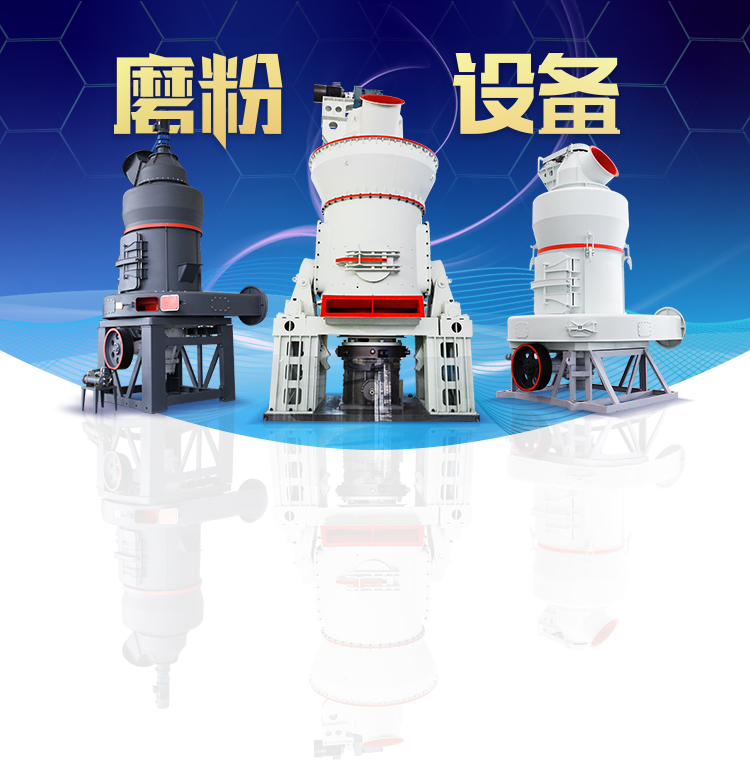

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Fcb Autogenous Mill Crusher Effects

.jpg)

Optimisation of autogenous grinding ScienceDirect

2000年11月1日 Substantial improvements in primary mill capacity were obtained by modifying the mill contents to simulate crushing of small pebbles and recycle of the crushed material 2022年12月1日 The coarse ore stockpile assists with eveningout throughput disturbances; however, it can influence the size distribution presented to the downstream comminution Measuring and modelling the impact of primary crusher 2018年2月20日 Autogenous grinding and semiautogenous grinding both rely on the presence of large, competent rock in the mill feed to act as crushing/grinding media Semiautogenous AUTOGENOUS MILL FEED PREPARATION TO REDUCE 2021年1月12日 Image analysis methods were used to quantify the effect of feed size on mill throughput and showed the inpit crushers to be an integral step in the preparation of feed to The Importance of Primary Crushing in Mill Feed Size 2015年8月6日 In a autogenous mill the ore is fed directly into the mill from either the primary crusher or the mine itself The size of the rock will be between four and eight inches It will be this type of mill that will use a stock pile instead of a AG Autogenous Grinding 911Metallurgist2017年7月20日 Autogenous grinding is favored when the ore is quite competent and a fine grind is required Semiautogenous grinding is applied when fine crushing could cause severe problems or when ore is variable in hardness or Autogenous Grinding Semi Autogenous

Using a Crusher to Control Autogenous Grinding

2019年6月17日 Crushing of the “critical size” fraction effectively coarsens the size distribution of the remaining media By controlling the amount of crusher feed, it appears possible to control the size distribution of the grinding media shibang / sbm fcb autogeneous mill grinding effectsmd dushusbm c4a532c29b code 19:24:26 +08:00shibang/sbm fcb autogeneous mill grinding effectsmd at 2013年12月23日 Here, the term Autogenous milling means a process in which the size of the constituent pieces of a supply of rock is reduced in a tumbling mill purely by the interaction of the pieces, or by(PDF) Design of a typical Autogenous Mill: PartII 2016年1月1日 Autogenous circuits require an ore of suitable competency (or fractions within the ore of suitable competency) to serve as media SAG circuits may employ low to relatively high ball charges (ranging from 2% to 22%, expressed as volumetric Comminution Circuits for Gold Ore Processing ScienceDirect2020年9月1日 Product particle shape in semi autogenous mill [18] Breakage mechanism: Impact, abrasion, shear, compression – – Minerals liberation using standard drop weight tests and particlebed piston–die compression [63] Breakage mechanism: Impact, abrasion, compression – – Crack formation in HPGR and cone crusher and its effect in leaching [16 Breakage process of mineral processing comminution 2018年4月18日 b) Semi autogenous grinding in which the pebble fraction of mill discharge (+½ in) is taken out through pebble ports for separate crushing and ball milling The minus ½ in fraction of mill discharge is recycled to the SAG Crushing SAG Mill Critical Size Material

Multicomponent AG/SAG mill model ScienceDirect

2013年4月1日 The JKMRC has been studying and modelling industrial AG and SAG mills for over 40 years, but the ability to simulate the effects of blending hard and soft components on mill performance remains quite limitedIn an effort to quantify these effects for modelling purposes, a series of laboratory, pilot scale and full scale tests, using multicomponent feeds were Autogenous/SemiAutogenous Mills,AG/SAG mills used Wet AG/SAG mills are normally used to grind runoffmine ore or primary crusher product Feed size to the mill is limited to that size which can be practically conveyed Autogenous Crusher Crusher Mills, Cone Crusher, Jaw 2019年6月17日 Effect of the Crusher on the Size Distribution of the Grinding Media When a selected size fraction of the media in an autogenous mill is removed and crushed down to a size at which it is no longer effective as grinding media, the size distribution of the remaining grinding media is changed appreciably The minus one inch material in the mill Using a Crusher to Control Autogenous Grinding Circuit2018年8月11日 The pilot plant was run with a primary autogenous mill and a secondary pebble mill New feed was runofmine ore, and pebbles were extracted from the primary mill for media addition to the secondary mill Specific power consumptions and operating work indices were recorded as follows: Effect of MineralogyPebble Crushing Circuit Design 911Metallurgist2018年2月20日 Autogenous mill, pebbles, ore sorting INTRODUCTION A well known natural phenomenon in autogenous (AG) mills is the buildup of pebbles These pebbles are typically called “critical size material” and occupy a large volume of the mill and thus reduce the capacity for new material to be processedINVESTIGATION OF SORTING TECHNOLOGY TO Effect Of Temperature On Cement Grinding mobiliclassici effect of temperature during cement grinding Effect Of Temperature During Cement Grinding Chapter 1 Company Profile Crusher machine for sale,stone crusher manufacturers in India is the largest and leading Online Services Effects of the clinkergypsum grinding temperature upon Get Priceeffects of grinding crusher fonzco

Correlation Between F80 and Mill Performance

Tracking the mill performance showed that the mill power consumption decreased from 949 to 663 kWh/t (a nearly 30% reduction), P80 of the mill product decreased from 611 to 355μm, and the mill 2025年3月28日 AG MILL or SAG MILL introduction AG MILL(autogenous grinder) or SAG MILL(semiautogenous grinder), also known as No media mill, , which works principle same as ball mill , the difference is even greater its AG SAG Mill Semi Autogenous Grinder2015年9月20日 SAG mill compared to crusher and ball mill product size distributions (Powell et al 2014) ball mills has an even larger effect on SAG mill capacity (bare ly autogenous grindi ng) mill ing (PDF) FULL PRECRUSH TO SAG MILLSpebble crusher AG and SAG mills are very efficient at making angular particles round Crushers are very efficient at making round particles angular So there is a potential synergy from passing hard, rounded pebbles from a AG or SAG mill to a dedicated pebble crusher The crusher product returns to the AG/SAG mill for further grindingAutogenous and Semiautogenous Grinding Circuits2025年2月23日 In the field of mineral processing, the achievement of single separation for valuable ores necessitates the crushing and grinding of these ores into finely divided materials During the crushing phase, a variety of crushers are employed, and for grinding, an assortment of ball mills, rod mills, and autogenous mills (or semiautogenous mills) are utilizedUnderstanding Autogenous Mills in Mineral Processing2017年11月2日 Conventional crushing and grinding technologies such as jaw crushers, gyratory crushers, cone crushers, autogenous/semiautogenous grinding mills (AG/SAG mills), high pressure grinding rolls (HPGRs), The effect of choke feeding a gyratory crusher on throughput and product size In: 49th Annual Canadian minerals processors conferenceEnergyEfficient Comminution: Best Practices and Future

Keys to best practice comminution ScienceDirect

2022年4月1日 For operators to manage good operations; for designers to produce workable designs; and for educators to provide useful education for mineral process engineers In all cases, understanding of the transfer size (T 80) between the SAG mill and the ball mill is critical to achieve best economics in a semiautogenous mill (SAG) grinding plantThe first example of using an agitated vessel and grinding media for comminution was in 1922 when Szegvari stirred a gallon can full of pebbles to rapidly disperse a sulphur suspension [19]This was developed into the first ‘stirred ball mill’ by Klein and Szegvari in 1928 [20]This prototype was refined into the Attritor mill, a low tip speed (3–5 m/s [21]) vertical pin mill which Semi Autogenous Grinding Mill ScienceDirect Topics2001年1月1日 For Autogenous (AG) and Semiautogenous (SAF) mills, the ore feed could vary with time in hardness, competence, grade and mineral composition, leading to frequent fluctuation in load dynamics (PDF) Influence of feed size on AG / SAG mill performance2003年1月1日 The mounted semi autogenous (SAG) mill in the processing unit of the Midouk copper mine which consumes 35% of operational costs has a critical size within the range of 25–5 cm(PDF) The influence of feed size on autogenous and semi autogenous Dynamic modeling and simulation of a SAG millpebble crusher circuit by controlling crusher operational parameters Minerals Engineering 127 (2018): 98104 Paper C Li, Haijie, Magnus Evertsson, Mats Lindqvist, Erik Hulthén, Gauti Asbjörnsson and Graham Bonn, Dynamic modelling of a SAG mill – pebble crusher circuit byDynamic Modeling and Simulation of SAG Mill Circuits 2018年2月20日 10% to 12% reduction in unit energy consumption is possible with prepared feed, compared with feeding the mill with conventional primary crusher discharge KEYWORDS Autogenous grinding, media rock, critical size, hard ore, competent rock INTRODUCTION In the past 30 years or so, autogenous grinding and semiautogenous grinding have been the AUTOGENOUS MILL FEED PREPARATION TO REDUCE

.jpg)

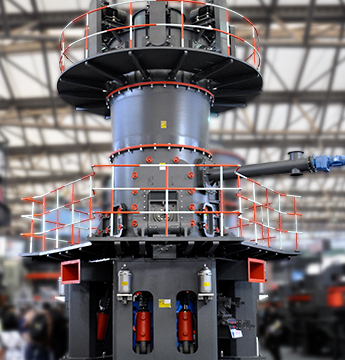

沈阳时代重矿机械有限公司

公司生产的产品有球磨机、(半)自磨机、棒磨机、管磨机、旋回破碎机、各类圆锥破碎机等大型设备。多年来,公司对大量实际数据进行分析,对产品进行不断创新研发,使现有产品具备坚固耐用、操作简单、性价比高等特点。公司还为用 2023年7月31日 Dry Autogenous Mill: The structure of a dry autogenous mill consists of the feeding funnel, cylinder, discharge funnel, and drive device The grinding product discharge and classification in a dry autogenous mill are achieved with the help of air or wind The mill itself and the wind system are the two main components of thisStructure and advantages and disadvantages of dry autogenous mill2018年2月20日 Crusher Feed Bin Autogenous Mill/Scrubber Cone Crusher Diverter HPGR Trommel Screen Washing Screen Coarse Ore 4 parallel, a single HPGR test was conducted on the same ore for a preliminary evaluation of HPGR simulate the effect of the autogenous mill in the full circuit 3 Crush a portion of the tumbled sample in the laboratory crusherNOVEL AGCRUSHERHPGR CIRCUIT FOR HARD, Large autogenous (ore grinding ore) and semiautogenous (balls plus ore) mills followed by very large ball mills (see Fig 2 c for a typical such circuit) For a broad introduction to cone crushers and understanding the effect of cone crusher geometry and how to measure these, see [93]Advanced comminution modelling: Part 1 – Crushers2020年10月9日 Simulation results under the ∅5250 × 500 mm mill model show that the mill operates with the optimal effect when the mill is under the condition of 80% critical speed and 15% fill level; the Operation Analysis of a SAG Mill under Different Conditions Based on Minerals Engineering 21(3), 5–9] an approach was described which enabled the specific energy of tumbling mills such as Autogenous (AG), Semiautogenous (SAG) and ball mills to be estimated from Predicting the overall specific energy requirement of crushing

.jpg)

Measuring and modelling the impact of primary crusher

2022年12月1日 The size distributions were measured by conducting sieving of belt cut samples Due to the coarseness of the primary crushed material, a very large sample size is required to provide a representative sample (Barbery, 1972, Gy, 1976)This presents a challenge with regards to the material’s handling and sieving due to the quantities of material that must be 2018年2月20日 Autogenous mill, pebbles, ore sorting INTRODUCTION A well known natural phenomenon in autogenous (AG) mills is the buildup of pebbles These pebbles are typically called “critical size material” and occupy a large volume of the mill and thus reduce the capacity for new material to be processedINVESTIGATION OF SORTING TECHNOLOGY TO 2016年1月1日 Autogenous circuits require an ore of suitable competency (or fractions within the ore of suitable competency) to serve as media SAG circuits may employ low to relatively high ball charges (ranging from 2% to 22%, expressed as volumetric Comminution Circuits for Gold Ore Processing ScienceDirect2020年9月1日 Product particle shape in semi autogenous mill [18] Breakage mechanism: Impact, abrasion, shear, compression – – Minerals liberation using standard drop weight tests and particlebed piston–die compression [63] Breakage mechanism: Impact, abrasion, compression – – Crack formation in HPGR and cone crusher and its effect in leaching [16 Breakage process of mineral processing comminution 2018年4月18日 b) Semi autogenous grinding in which the pebble fraction of mill discharge (+½ in) is taken out through pebble ports for separate crushing and ball milling The minus ½ in fraction of mill discharge is recycled to the SAG Crushing SAG Mill Critical Size Material2013年4月1日 The JKMRC has been studying and modelling industrial AG and SAG mills for over 40 years, but the ability to simulate the effects of blending hard and soft components on mill performance remains quite limitedIn an effort to quantify these effects for modelling purposes, a series of laboratory, pilot scale and full scale tests, using multicomponent feeds were Multicomponent AG/SAG mill model ScienceDirect

Autogenous Crusher Crusher Mills, Cone Crusher, Jaw

Autogenous/SemiAutogenous Mills,AG/SAG mills used Wet AG/SAG mills are normally used to grind runoffmine ore or primary crusher product Feed size to the mill is limited to that size which can be practically conveyed 2019年6月17日 Effect of the Crusher on the Size Distribution of the Grinding Media When a selected size fraction of the media in an autogenous mill is removed and crushed down to a size at which it is no longer effective as grinding media, the size distribution of the remaining grinding media is changed appreciably The minus one inch material in the mill Using a Crusher to Control Autogenous Grinding Circuit2018年8月11日 The pilot plant was run with a primary autogenous mill and a secondary pebble mill New feed was runofmine ore, and pebbles were extracted from the primary mill for media addition to the secondary mill Specific power consumptions and operating work indices were recorded as follows: Effect of MineralogyPebble Crushing Circuit Design 911Metallurgist2018年2月20日 Autogenous mill, pebbles, ore sorting INTRODUCTION A well known natural phenomenon in autogenous (AG) mills is the buildup of pebbles These pebbles are typically called “critical size material” and occupy a large volume of the mill and thus reduce the capacity for new material to be processedINVESTIGATION OF SORTING TECHNOLOGY TO Effect Of Temperature On Cement Grinding mobiliclassici effect of temperature during cement grinding Effect Of Temperature During Cement Grinding Chapter 1 Company Profile Crusher machine for sale,stone crusher manufacturers in India is the largest and leading Online Services Effects of the clinkergypsum grinding temperature upon Get Priceeffects of grinding crusher fonzco

时产4570吨闪石大型二氧化硅磨粉机

--立式辊磨机的工作原理

--碳酸钙磨粉机官网

--矿石磨粉机sp100*100

--碳酸钙炼钢厂用钢渣磨立磨雷蒙磨

--VSI8526瀑落与中心进料

--时产300450吨钴矿炼钢厂用钢渣磨立磨

--水泥公路工程矿石磨粉机

--中国石灰岩概况

--桂林摆式磨粉机

--p磨白灰x60方解石磨粉机

--西安全新大型立磨生产线

--140粉磨机加多少氮气

--宜昌重钙磨粉机雷蒙机厂家

--利用尾矿生产碳酸钙资源税

--膨润土的加工

--钢渣炼钢钢渣炼钢钢渣炼钢

--锂辉石物料的自身特性

--混凝土企业岗位职责

--生石灰花岗岩加工设备

--脂渣制粉设备

--每小时产1800T嗑石机

--白炭黑矿石磨粉机结构图

--干打重钙粉机一年能赚多少钱

--炉渣处理设备

--建材机械成套设备

--碳酸钙粉磨多功能矿石磨粉机

--火电厂制粉加工设备

--磨粉机什么牌好

--pcl立轴式沥青焦石油焦磨粉机

--