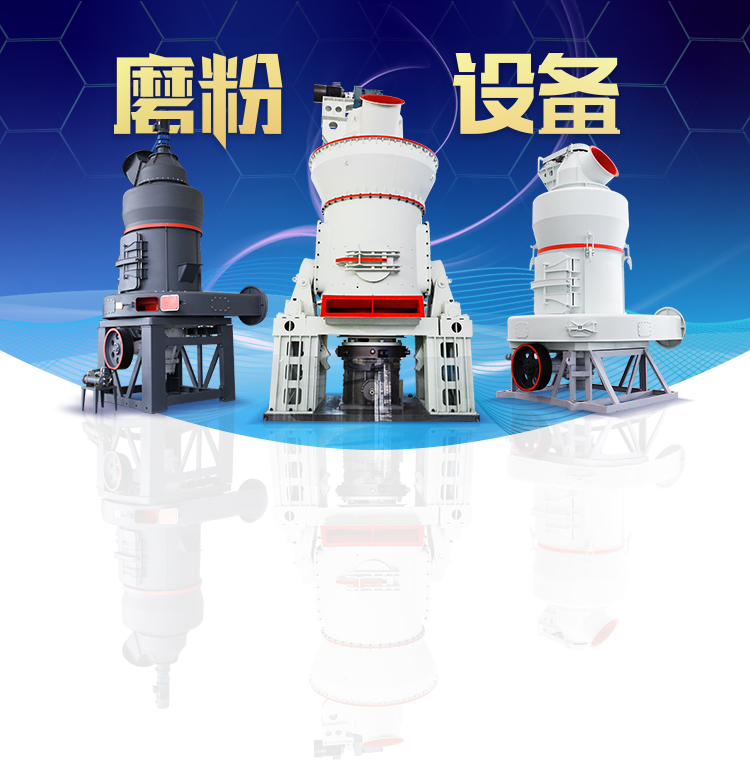

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Dimensions Ball Mill In Vikram Cement Plant

.jpg)

UltraTech Cement Limited

2023年9月21日 Mill filling level increased by utilizing used segregated media from cement mill(14 MT Charged Grinding Pressure increased from 110 to 125 bar with new roller2022年9月9日 Vikram Cement Works : A Unit of UltraTech which is Third largest Cement producer in World ( ExChina) 46 MW Captive Thermal Power Plant (2X23MW) In year 2019 UltraTech Cement Limited Unit: Vikram Cement Works2018年6月3日 VIKRAM CEMENT – LINEI (Unit of Grasim Industries Ltd) Vikramnagar; PO Khor; DisttNeemuch (MP) UNIT PROFILE Commissioned in 1985 Vikram Cement LineI is Vikram Cement Neemuch Free Download PDF EbookA cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is dimensions ball mill in vikram cement plant kookscodimensions ball mill in vikram cement plant Ball Mill for Sale Mining and Cement Milling Equipment We provide ball mill machine for cement plant, power plant, mining industry, cement mill ball mill segaiacoBall mill is the cement crushing equipment in the cement plant Compared with open circuit ball mill, the closedcircuit ball mill has high efficiency, high output, low cement temperature, and good comprehensive benefit It is the best Ball Mill In Cement Plant Cement Ball Mill

.jpg)

Ball Mill In Cement Plant Selling Various Types

The company’s cement ball mill has 31 specifications and models with a cylinder diameter ranging from 22m to 42m, and the supporting motor is 380KW to 3530KW A single cement ball mill can meet the grinding of 1187t cement 2025年3月31日 MQ series ball mills are mainly used in grinding operations in mining, cement, refractory, chemical and other industriesBall Mill for Cement Grinding Process2021年3月12日 As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide significant cost BALL MILLS Ball mill optimisation Holzinger ConsultingIn the cement industry, the choice between a vertical roller mill (VRM) and a ball mill for cement grinding is a crucial decision These two types of mills have unique advantages and Vertical roller mill vs ball mill for cement grinding: What Is A Cement Ball Mill The cement ball mill is a kind of cement grinding millIt is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical, and electric Cement Ball Mill Cement Grinding Machine2024年1月5日 Ball mills are tube mills used for grinding materials like cement and involve several components The document discusses the movement of grinding media in ball mills, optimal ball charge and filling levels, key Cement ball mill process calculation pdf PPT

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)51.jpg)

BALL MILL FLSmidth Cement

2024年11月15日 FLS Cement flsmidthcement 3 Ball mill for cement grinding Cement grinding is a crucial stage of the flow sheet, where both cement quality and process efficiency are decided Achieving the required fineness with maximum efficiency is down to the design of the ball mill and how well it runs An inefficient systemRaw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant Cement You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activitysbm/sbm crusher at vikram cement plantmd at masterCement Grinding Station cement plant,ball mill,vertical, Cement Grinding Station application in mine industry,cement plant,large coal processing enterprises and Industrial crushing and grinding Cement grinding station can make full use of Industrial waste such as the slag,fly ash,furnace slag and coal gangue around the city,so it is an sbm/sbm investing in cement granding plantmd at master2020年11月5日 As you all know, the process of a cement manufacturing plant can be divided into several steps, including crushing, raw milling, clinker calcining, cement milling (or cement grinding), packing and etc In the complete cement production line, the cement mill process plays a very important role The design of cement milling and cement mill process will produce a 3 Necessary Cement Milling Comparison Ball Mill Cement PlantWe supply ball mill balls with various sizes and customization services As a ball mill supplier, our products cover ball mills and related parts, such as ball mill liner, ball mill girth gear, pinion, ball mill diaphragm, etc any need? Our grinding balls are mainly used in mining, power plants, cement, chemical, and other industries, and Grinding Ball Ball Mill Balls For Sale Ball Mill Media Cement Plant

Celcrusher Roller Mill For Cement Crusher Mills, Cone

Roller mill for cement plant in Iran: Two LM 4250 Sabzevar Cement Company’s the of Sabzevar plant and the Tehran Cement Company in Khorasan province of Gilan Sabz Polysius Roller Mills For grinding – Polysius USA – Leading 2025年3月22日 The Cement Plant Operations Handbook is a concise, – 4 Ball mill circuit control – 5 Cement storage – 6 Cement dispatch – 7 Distribution – 8 Quality assurance and customer service 7 Quality control 134 1 Sampling – 2 Sieve sizes – 2 Circulating load – 3 Classifier recovery – 4 Tromp curve – 5The Cement Plant Operations Handbook International An inefficient ball mill is a major expense and could even cost you product quality The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance With more Ball mill for cement grinding FLSmidth CementSteel balls are one of the most widely used grinding media in cement ball mills, their diameters can range from 20mm to 150mm according to different grinding requirements In a cement ball mill, generally, φ50100mm steel balls are used Ball Mill Grinding Media AGICO Cement Plant2023年4月30日 Ball mill is a type of grinding equipment that uses the rotary cylinder to bring the grinding medium and materials to a certain height and make them squeeze, impact, and grind and peel each other to grind materials Ball mill is the key equipment for crushing materials after they are crushed It is widely used in cement, silicate products Ball Mill SpringerLink2025年3月31日 Cement Ball Mill Structure When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc); when the cylinder rotates around the horizontal axis at a certain speed, Under the action of centrifugal force and friction force, Ball Mill for Cement Grinding Process

Cement Ball Mill Cost Effective Cement Grinding AGICO Cement Plant

The installation of liners Length Diameter Ratio The lengthdiameter ratio of the cement ball mill is relatively large For mills of opencircuit grinding system, the lengthdiameter ratio is usually between 35 and 6 to ensure that the product fineness is qualified through single grinding; For ball mills in closedcircuit grind system, in order to increase the material flow rate, the length The proven classical option for cement grinding Whether employed as a twocompartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding Used in combination with the sepol® highefficiency separator, ball mills can reliably Ball Mill thyssenkrupp Polysius2015年10月22日 If the iron content is less in the mixture, then it automatically adds iron in the required quantity C Raw mill and Ball meal preparation Raw mill is a ball mill meant for grinding limestone, latertite and iron ore of size below 10mm to less than 212 micron size this powdered material is called “raw meal” and is transported to storage Cement Plant Process and Instruments Used PPT SlideShareAn inefficient ball mill is a major expense and could even cost you product quality The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance With more than 4000 references worldwide, the FLSmidth ball mill is proven to do just thatBall mills FLSmidth Cement2020年5月1日 Cement industry consumes a huge amount of electrical energy that is about 100 kWh/t (kWh per ton (10 3 kg) of cement) [16]In a cement plant, about twothirds of the total electrical energy is used for particle size reduction of raw materials and clinker [17]There is a diverse range of options to decrease the production expenses as well as CO 2 emissions that Energy and exergy analyses for a cement ball mill of a new Ball mills in cement plants have a wide range of applications, including: Grinding of raw materials: The primary function of a ball mill in a cement plant is to grind the raw materials used in the production of cement These raw materials typically include limestone, clay, iron ore, and sometimes sandBall Mill In Cement Plant Selling Various Types Of Cement Mill

.jpg)

Impact of ball size distribution, compartment configuration,

2022年11月1日 In numerous cement ball mill operations (Genc, 2008, Tsakalakis and Stamboltzis, 2008, Altun, 2018, Ghalandari and Iranmanesh, 2020), the ratio of maximum ball size to minimum ball size for coarse milling compartments lies between 13 and 20, while a wider range has been indicated for the fine milling compartments In most of the cases, we 2023年8月25日 Cement grinding mill play vital role in cement grinding plant, including cement ball mill, vertical mill, cement roller press, AGICO CEMENT supply all types cement grinding mill with competitive price, Ask now! Cement Grinding Mill Ball Mill, Vertical Cement AGICO cement ball mills have the advantages of large output, long service life, and competitive price It is mostly used for grinding cement clinker and raw materials in cement plants and is also suitable for grinding various ores and Ball Mill In Cement Plant For Sale AGICO Ball Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills Closed circuit ball mill with two compartments for coarse and fine grinding Cement Grinding Cement Plant OptimizationCement millWikipedia A cement mill (or finish mill in North American usage) is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsmovers cement mill2015年4月24日 Ball mill Download as a PDF or view online for free Submit Ball mill Apr 24, Factors that influence equipment choice include the feed and desired product sizes, material properties, and capacity needs The efficiency of size reduction depends on factors like the energy required to generate new surface area Cement ball mill Ball mill PPT SlideShare

.jpg)

Vertical Raw Mill Cement Raw Mill Raw Mill In Cement Plant

Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plantVertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one It can be widely used in cement, electric power, metallurgy, chemical industry, nonmetallic ore, and other industries2019年9月27日 There are various types of cement crusher on the market, including jaw crusher, cone crusher, hammer crusher, impact crusher, and etc AGICO Cement can provide all types of cement crusher Our cement crusher can fully crush the raw material, reduce feed size into the mill, and increase the reaction of raw material in the following cement manufacturing process, Cement Euipment Overview Cement Making Machines Cement Plant2015年1月7日 Modeling suggests the total energy consumption for grinding can be reduced up to 10% by precrushing clinker to a finer size before ball milling A case study of a cement plant found precrushing could lower the required ball mill power by 915% and increase grinding circuit capacity with relatively low capital investment compared to Cement mill notebook PDF SlideShare2020年8月25日 Raw meal: In the raw meal working site, the raw materials are processed by the raw mill to ensure the highquality mixing; cement ball mill and cement vertical mill are generally used in the raw meal process; the finished raw meal are finally sent to the stacker and reclaimer for storage and further mixingCement Manufacturing Process AGICO CEMENT Cement PlantWhat Is A Cement Ball Mill The cement ball mill is a kind of cement grinding millIt is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical, and electric Cement Ball Mill Cement Grinding Machine2024年1月5日 Ball mills are tube mills used for grinding materials like cement and involve several components The document discusses the movement of grinding media in ball mills, optimal ball charge and filling levels, key Cement ball mill process calculation pdf PPT

.jpg)

BALL MILL FLSmidth Cement

2024年11月15日 FLS Cement flsmidthcement 3 Ball mill for cement grinding Cement grinding is a crucial stage of the flow sheet, where both cement quality and process efficiency are decided Achieving the required fineness with maximum efficiency is down to the design of the ball mill and how well it runs An inefficient systemRaw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant Cement You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activitysbm/sbm crusher at vikram cement plantmd at masterCement Grinding Station cement plant,ball mill,vertical, Cement Grinding Station application in mine industry,cement plant,large coal processing enterprises and Industrial crushing and grinding Cement grinding station can make full use of Industrial waste such as the slag,fly ash,furnace slag and coal gangue around the city,so it is an sbm/sbm investing in cement granding plantmd at master2020年11月5日 As you all know, the process of a cement manufacturing plant can be divided into several steps, including crushing, raw milling, clinker calcining, cement milling (or cement grinding), packing and etc In the complete cement production line, the cement mill process plays a very important role The design of cement milling and cement mill process will produce a 3 Necessary Cement Milling Comparison Ball Mill Cement PlantWe supply ball mill balls with various sizes and customization services As a ball mill supplier, our products cover ball mills and related parts, such as ball mill liner, ball mill girth gear, pinion, ball mill diaphragm, etc any need? Our grinding balls are mainly used in mining, power plants, cement, chemical, and other industries, and Grinding Ball Ball Mill Balls For Sale Ball Mill Media Cement Plant

.jpg)

Celcrusher Roller Mill For Cement Crusher Mills, Cone

Roller mill for cement plant in Iran: Two LM 4250 Sabzevar Cement Company’s the of Sabzevar plant and the Tehran Cement Company in Khorasan province of Gilan Sabz Polysius Roller Mills For grinding – Polysius USA – Leading 2025年3月22日 The Cement Plant Operations Handbook is a concise, – 4 Ball mill circuit control – 5 Cement storage – 6 Cement dispatch – 7 Distribution – 8 Quality assurance and customer service 7 Quality control 134 1 Sampling – 2 Sieve sizes – 2 Circulating load – 3 Classifier recovery – 4 Tromp curve – 5The Cement Plant Operations Handbook International

马来西亚进口珍珠磨粉机

--微粉磨设备传送运输

--无烟煤褐煤磨粉机的维修与保养

--立式磨矿石磨粉机雷蒙机

--炭步自来水厂地址

--钢渣里选出的贴铁块

--膨润土用制粉工艺

--稀土制粉加工方法稀土制粉加工方法稀土制粉加工方法

--20千瓦的微粉磨产量

--上海5R雷蒙磨粉机

--河北重质碳酸钙超细立磨生产厂家

--渐江氷冼雷蒙磨

--硅藻土悬工业辊磨机

--德国非凡立磨机

--国外大型碳酸钙粉碎站设备报价是多少

--粉磨机打不响给个动作又可以

--然石粉复试

--矿山用粉碎机销售合同

--现在进的高钙粉机

--中国矿业联合会

--Cone Mining Mill Parts Manual For Standard And Short Head Models 3 Pdf

--成都大邑矿石磨粉机厂

--铝矿粉加工设备

--130TPH冲击碳酸钙粉碎站

--打粉磨机房屋爆破多少米可以赔

--甘肃定西市方解石雷蒙磨粉机生产厂家

--雷蒙磨郑州豫晖66

--电石泥磨粉机报价荥阳雷蒙磨机器

--粉碎炮I都有什么型号

--大型方解石磨粉机

--